With Brexit and the U.S. presidential race dominating the headlines, you might have missed a recent archeological discovery made in Boston. Construction workers in the Seaport District found what experts believe is the world’s oldest supply chain analyst report. It is written in cuneiform on a clay tablet, which archaeologists estimate dates back to around 3200 BCE. The author is unknown, but based on a preliminary translation, the report’s subject matter is very familiar to supply chain professionals today. What does the report say?

“Supply chain visibility and collaboration are critical for success,” reads the opening sentence, and the rest is familiar commentary.

Okay, so construction workers in Boston did not find an ancient supply chain analyst report buried underground (but they did find the remains of a shipwreck), but I used this fictional story in the presentation I gave at Elemica’s Executive Luncheon last week in Germany to discuss the following question: If for decades (maybe even centuries) analysts, consultants, software vendors, and others have been writing reports and giving presentations about the importance of supply chain visibility and collaboration, why are we still talking about it today? In other words, why are companies still falling short on these objectives?

You can download my presentation below, but the short answer is that…

There is no silver bullet for supply chain visibility. As I’ve written before, despite all the buzz about supply chain visibility software, it’s a worthless investment if companies don’t also invest the time, money, and resources to see and walk their supply chain, from start to finish, with their own eyes and feet. Simply put, achieving true end-to-end supply chain visibility takes considerable more time, money, and resources than many companies are investing today.

It’s a moving target: Supply chain networks, technologies, regulations, business models, and competitors are continuously changing, and as a result, so are the rules for success. Simply put, just when you think you’ve made progress and have it all figured it out, the rug is pulled out from under you (see Brexit).

And when it comes to collaboration, many companies still confuse cooperation with collaboration, and they’ve made little progress in transforming the way they establish and manage business relationships, due in part to a lack of trust.

I ended my presentation by sharing some advice and recommendations for how to improve supply chain visibility and collaboration, which I’ve written about in many blog posts, including most recently in Made in “I Really Don’t Know” and Getting that “Swing” in Supply Chain Management.

Back to technology, although it is not a silver bullet solution, it is a critical piece of the visibility and collaboration puzzle. When it comes to achieving alignment with suppliers, customers, logistics service providers, and other external trading partners, two large hurdles have traditionally stood in the way: dealing with disparate IT systems, both within a company’s four walls and across their trading partner network, and connecting electronically with hundreds, or even thousands, of trading partners in a cost-effective and timely manner.

Leading companies have made two important realizations to help them overcome these hurdles:

- Their ERP system, which was originally designed for inside-the-four-walls business processes and for companies that were more vertically integrated than they are today, is not the best platform for cross-company communication and collaboration.

- Business-to-Business (B2B) connectivity — that is, creating and managing thousands of one-to-one connections with their trading partners, typically using outdated technology like Electronic Data Interchange (EDI) — is not a core competency.

Simply stated, when it comes to supply chain and logistics processes, leading companies are recognizing that the best platform moving forward is a Supply Chain Operating Network (SCON).

Evonik Industries, a leading specialty chemicals company, is a perfect example. Heinz-Günter Lux, Head of Business Process Management at Evonik, also presented at the luncheon. He talked about the company’s path to an e-business process integration platform. Evonik defines e-business as “the digital integration of business processes including the entire electronic information flow to efficiently execute all types of operational business processes between all business partners.”

An important step in the company’s journey was standardizing and simplifying its internal processes and ERP environment. But echoing my point above, Evonik recognized that ERP was not the right platform for cross-company communication and collaboration. As Mr. Lux put it, “the architecture has to connect the efficient internal ERP world with a dynamic external world.” After evaluating 15 solution providers, Evonik selected Elemica (a Talking Logistics sponsor) as its e-business integration layer and platform.

A couple of other interesting takeaways from Mr. Lux’s presentation:

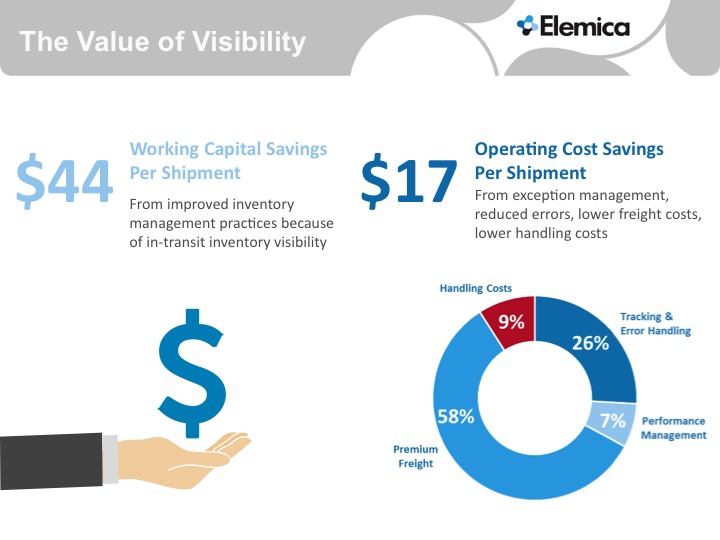

- A big part of the business case for this initial stage of the journey, which was focused on process efficiency, was eliminating the costs and errors associated with manual data entry. The company estimates it is saving 10 to 15 euros per transaction, which correlates well with Elemica’s research and experience with other customers.

- Mr. Luxe strongly believes in having a single point of contact or champion for driving e-business transformation. Why? For many of the reasons I discussed in Here Comes the Chief Network Effects Officer.

Will we ever stop writing and talking about the importance of supply chain visibility and collaboration? Probably not, but as more companies like Evonik start leveraging the power of a supply chain operating network, the story should get better with time.