Historically, there has been a disconnect between Supply Chain Planning and Supply Chain Execution processes and applications. As a result, companies tend to plan, optimize, and execute their inventory, labor, transportation, and warehousing operations separately (that is, in a siloed manner). Is that the case at your company? What are the main problems caused by poorly integrated/synchronized supply chain planning and execution processes? What are the biggest obstacles you face in bridging the gap between supply chain planning and execution processes?

In a July 2024 survey, we asked those questions to members of our Indago supply chain research community — who are all supply chain and logistics executives from manufacturing, retail, and distribution companies — and to members of Manhattan Associates’s supply chain planning product council. For a summary of the research results, download the ebook published recently by Manhattan Associates. The following is an excerpt of the findings.

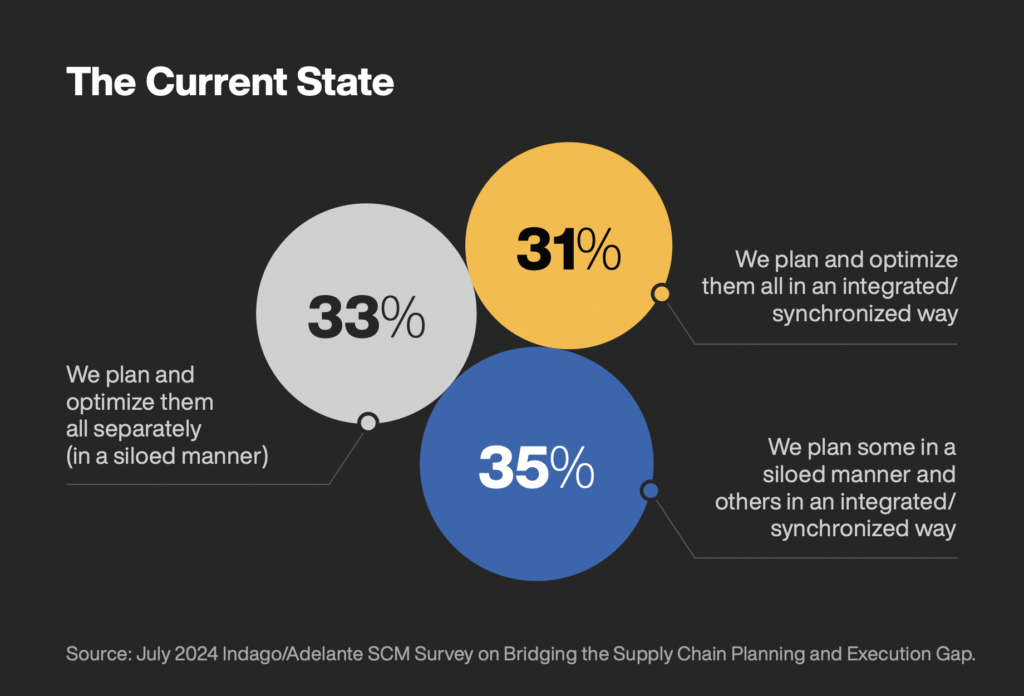

Only 31% of the respondents said they currently plan and optimize their inventory, labor, transportation, and warehouse operations in an integrated/synchronized way. Most either plan, optimize, and execute these functions in a siloed manner, or they plan/optimize some functions together and others separately.

For example, one supply chain executive commented, “We are synchronized for transportation and warehouse operations (including labor) and organized separately for inventory planning.” Another executive said, “From an execution standpoint, our teams are able to access the demand planning dashboard but have not been able to fully utilize the information to influence our preparation for volume swings.”

The survey results also show that while a lack of technology capabilities is a key obstacle to bridging the supply chain planning and execution gap — as evidenced by the number of respondents who said they still rely on Excel spreadsheets or manual processes for some supply chain functions — there are other big obstacles to overcome, specifically the lack of cross-functional metrics and change management issues. The following comments illustrate these challenges:

“When I first arrived at my company, we were completely siloed between operations (warehousing, logistics) and planning. About 2 years ago, the planning group was put into my structure, and we began to integrate our processes. The biggest issue we face now is that the supply chain and sales teams are incentivized so differently. It is a constant battle between bringing in too much inventory or not enough; this ties up significant capital in our on-hand inventory that could be utilized elsewhere if we were more streamlined.”

“Bridging the gap between planning and execution starts with the top of supply chain leadership. Planning and execution need to be aware of what the other is [doing] and make sure that planning and forecasting is realistic… A single architecture or platform would be ideal; however, I have seen trouble ‘translating’ the same data between different groups of the organization. For example, Sales focuses on revenue numbers, Planning might focus on purchased units, Logistics might focus on cartons and containers, and all these numbers need to be planned and forecasted in the same manner otherwise each department might take liberties or adjust the numbers from the top to translate it into what matters most for them.”

“Ultimately, everyone must share the same goals for success and the metrics for measuring them. When you realize this can only be achieved through the same resource pool, usually dollars, you will have the ideal situation. In theory this could be done by having a single supply chain platform/architecture that everyone uses. But you face this issue of conversion and adoption in existing businesses.”

“Cross functional collaboration with departments/internal customers needs to improve to bridge some of these gaps.”

“Change management is an issue in environments where habits and work culture are strong and reinforced by authorities, but collaborative processes are not the priority.”

What are the main problems caused by poorly integrated/synchronized supply chain planning and execution processes? What are the biggest obstacles companies face in bridging the gap? For answers to those questions and additional insights from the research, please download the ebook. Then post a comment and share your perspective on this topic!