When you spend your workday thinking and writing about logistics, you can’t help but see it in your everyday life too. Here are two examples that I experienced last week, courtesy of Amazon and AAA.

Amazon: Two Extremes of Packaging

My wife walked into the study with a large box from Amazon. Inside was a small item, utilizing maybe 10 percent of the box’s volume. “Hey, Mr. Logistics Expert,” she says to me, “why does Amazon do this? Why do they put a small item in such a big box instead of using a shipping envelope?”

.@Amazon, still shipping a lot of air! A lot of wasted space, materials, and $. Need better collaboration between #logistics & packaging! pic.twitter.com/DXexFsj0pp

— Adrian Gonzalez (@talkinlogistics) June 7, 2017

“Because they can,” I said. “Because the box was there. Because despite all the adoration Amazon receives for its logistics operations, they’re no different than so many other companies that waste a lot of money, materials, and space shipping air.”

One of my supply chain predictions for 2016 was that there would be a lot less air shipped in boxes, trailers, and containers in the year ahead. As I wrote at the time:

One of the biggest opportunities to reduce transportation costs and carbon emissions is to reduce the number of trucks required to ship products by developing smarter packaging and product designs.

Earlier this year, for example, the Wall Street Journal published an article highlighting how IKEA is designing its packaging with shipping in mind, which for one product alone is translating into almost 7,500 trucks being removed from the road annually.

The WSJ also published an article about Sealed Air Corporation’s new iBubble Wrap. Unlike the original Bubble Wrap, this new version is sold as flat plastic sheets that customers fill with air at their locations using a custom-made pump. Because the product ships as flat sheets instead of bulky rolls, one truckload of iBubble Wrap contains as much packing material as 47 truckloads of the old product!

The shift to dimensional weight pricing by UPS and FedEx for all ground packages in the U.S. and Canada has been another driving force for shippers to pay more attention to packaging. The bottom line is that shipping small items in large boxes just got a lot more expensive.

Despite my prediction, it seems like the industry still has a long way to go.

It’s why last month UPS and Sealed Air Corporation announced “the opening of a Packaging Innovation Center in Louisville, Kentucky on the UPS Supply Chain Solutions campus…to help solve the packaging and shipping challenges of e-commerce retailers, and companies in many other industries, by maximizing efficiency, minimizing waste, reducing shipping costs, and increasing brand affinity.”

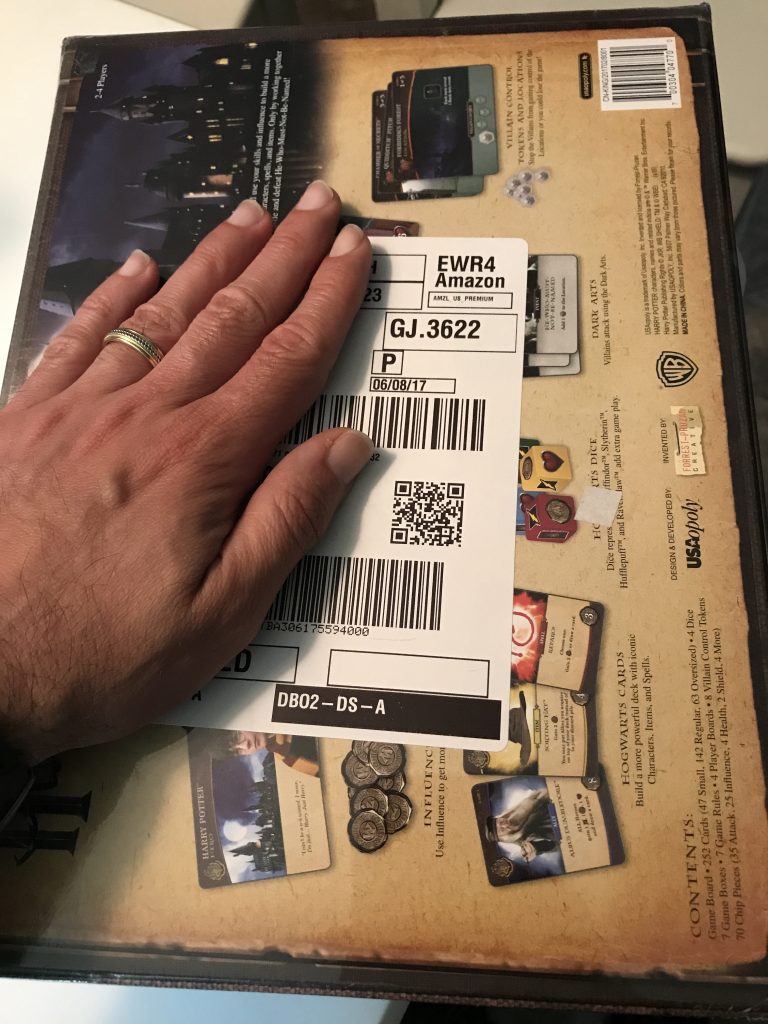

Back to Amazon, the next day we received the following shipment, a Harry Potter board game:

The shipping label was affixed right on the item. No box, no bubble wrap, no additional packaging! Brilliant.

One day, an excess of packaging, the next day, the complete absence of packaging. I guess it averages out to…average.

(For related commentary, see Bubble Wrap Loses Its Pop for Logistics Cost Savings and The Better Goal: More Fuel Efficient Trucks or Using Fewer Trucks?)

AAA: Excellence in Last-Mile Delivery Experience

“Um, Papi, there’s a big bubble in mom’s back tire and it’s leaking air,” my daughter says to me when she comes into the house. I go outside and inspect the car tire, one of four new ones we had just bought a few days earlier, and there it was, a large bulge on the sidewall.

I haven’t changed a tire in years, and because I didn’t have the time or patience to do it, I decided to call AAA for help (it’s why I’m a member, afterall).

I haven’t changed a tire in years, and because I didn’t have the time or patience to do it, I decided to call AAA for help (it’s why I’m a member, afterall).

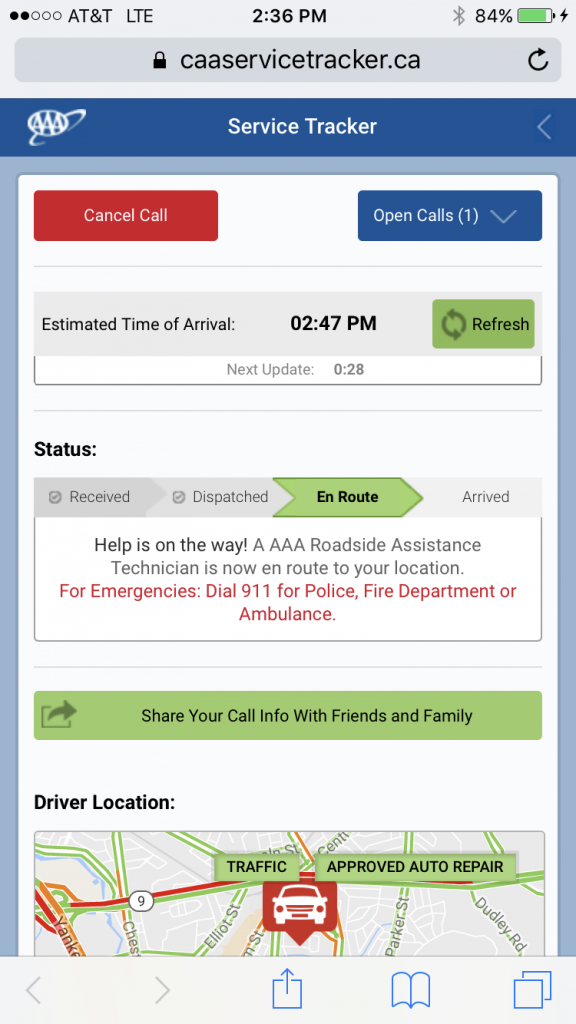

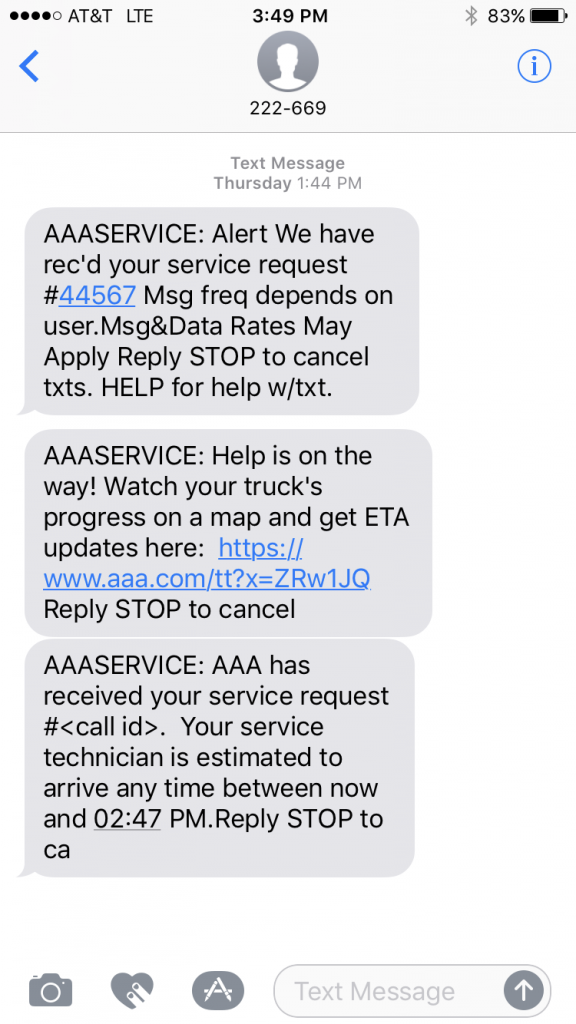

After I spoke with the customer service agent and explained my situation, he initiated the service request and I received a text message on my phone confirming the request. About 10 minutes later I received another text message informing me that a service technician had been dispatched, with a link for me to track his progress and estimated time of arrival (ETA).

The link brought me to page that showed the ETA of the service technician (automatically refreshed every 30 seconds), the status of the service request (Received, Dispatched, En Route, and Arrived), and a map showing the real-time location of the driver, similar to the way you can track your Uber driver.

The service technician arrived as promised in less than an hour, and 15 minutes later, the job was done.

Contrast that experience with the one I had a couple of months earlier with the garage door repair company. I received a voicemail the day before informing me that the repair technician would be at our house between 8:00 am and 12:00 pm the next day. Would it be closer to 8:00 am or closer to 12:00 pm? Was I the first stop on his route or the tenth stop? No idea, which meant I had to block out the four hours on my work schedule and wait. To make matters worse, the noon hour came and went and still no repair technician — and no phone call or text from him or the company notifying me of the delay. My wife finally called the company at 1:00 pm and was given a lame explanation that an emergency had come up which had delayed the driver.

Okay, I get it, unexpected things happen, but why not call or text me proactively with an apology and updated ETA?

“He’ll be there soon,” the customer service agent told my wife; he showed up about half an hour later.

The bottom line: whether you’re delivering products or services the final mile, follow AAA’s lead. Offer customers narrow, predictable, and reliable delivery time windows (assuming you have the right people, processes, and technologies in place to meet those expectations successfully), and provide them with real-time visibility to delivery status via mobile technologies and easy-to-use apps.

The days of keeping customers waiting for hours in the dark not knowing when you’re going to arrive are quickly coming to an end.