What do we need to unlearn in supply chain management?

I first addressed that question in a July 2017 post titled “Unlearning Supply Chain Management.” That post inspired us to ask our Indago supply chain research community a similar question last summer (June 2020):

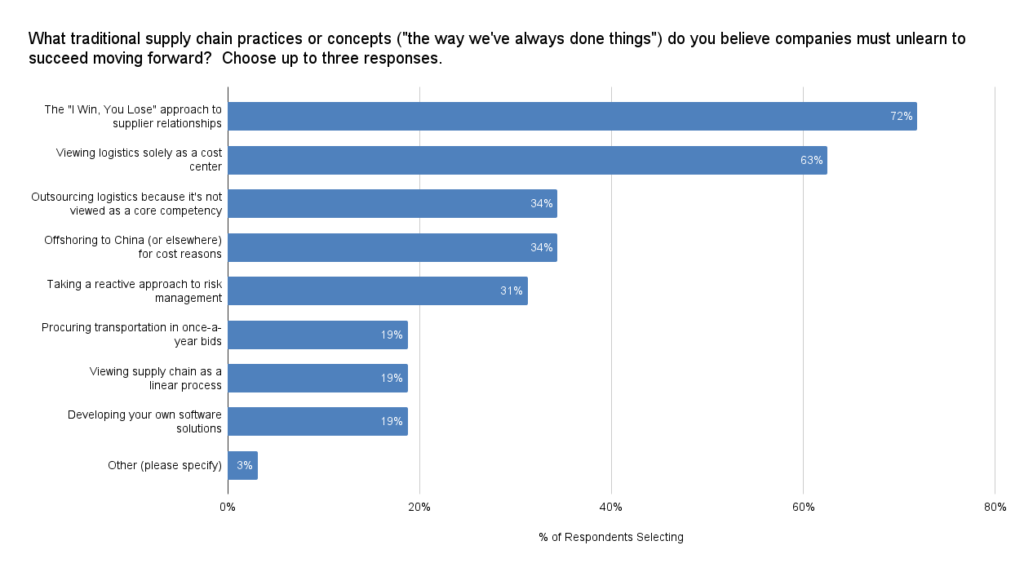

“What traditional supply chain practices or concepts (‘the way we’ve always done things’) do you believe companies must unlearn to succeed moving forward?”

The top two choices selected by the Indago respondents were “The ‘I Win, You Lose’ approach to supplier relationships” (72%) and “Viewing logistics solely as a cost center” (63%).

Here are some value-added comments from our Indago members, who are all supply chain and logistics professionals from manufacturing, retail, and distribution companies:

“In the coming years supply chains will be the focus of many companies, so viewing the operation as more than a cost center but as a driver of the business [will be] important, [as well as] viewing partnerships as strategic and worth investing in.”

“Offshoring to China would be the most challenging [practice to unlearn] but most beneficial. Long lead times offset by cheap labor had many companies in a tough situation during the COVID pandemic.”

“As shown by the pandemic and subsequent economic downturn, you cannot be reactive in risk management. You have to understand where your suppliers are and their suppliers, etc. Waiting until your suppliers are having issues is not the time to seek out alternative suppliers. Companies should be doing a thorough risk analysis review of their entire supply chain and implementing/updating a risk mitigation plan.”

“Better companies no longer view logistics as solely a cost center. The truth is logistics performance can have a big impact on sales — for example, by delivering consistently on-time and in-full or providing frequent service to the best customers.”

“Regarding risk management, the recent pandemic has pulled back the curtain and exposed some organizations that were not proactively managing risk. Thankfully, my organization was in a good position to continue operating smoothly under the circumstances. The ‘I win, you lose’ approach is the most important thing to unlearn. This approach is short-sighted and leads to poor collaborative relationships and poor service.”

Do you agree with our Indago members? Any other supply chain practices or concepts you believe companies must unlearn to succeed moving forward? Post a comment and share your perspective!

Join Indago

If you’re a supply chain or logistics practitioner from a manufacturing, retail, or distribution company, I encourage you to learn more about Indago and join our research community. It is confidential, there is no cost to join and the time commitment is minimal (2-5 minutes per week) — plus your participation will help support charitable causes like JDRF, American Logistics Aid Network, American Cancer Society, Feeding America, and Make-A-Wish.

You can also follow us on LinkedIn to stay informed of our latest research results and news.