Kevin O’Meara, Vice President, Integrated Supply Chain at Shaw Industries, posted the following question on Twitter last Friday:

“Have the billions of dollars invested in supply chain technology really made a significant difference in the outcomes? We have spent the money and we see unprecedented delays, shortages, and disruptions. [For example], we have no lack of visibility of our inbound ships yet we have unprecedented numbers of ships stacked up at anchor. We think it is ‘great’ when there are only 20 of them there.”

In response to someone who commented about the value of supply chain visibility tools, Kevin added, “I guess my point is I never needed a lot of ‘visibility’ [in the past] because the freight used to transverse the ocean and arrive like clockwork. Now I have great visibility so I can know the stuff will be 4 weeks late. I enjoyed the former situation a lot more.”

In a blog post yesterday, Kevin shared additional thoughts on this topic, including how he gauges whether outcomes are improving:

The aggregate outcome metric I like to use is the US Business Logistics Costs as a percent of the nation’s GDP. After all the technology improvements we have made, in 2021, this cost was 8% of GDP which, according to the 2022 State of Logistics report issued by CSCMP, has not been this high since 2008.

The disconnect Kevin highlights between the large investments companies have made in supply chain technology and the seemingly lack of improvement in outcomes is due, in part, to the disconnect between the Physical Supply Chain and the Digital Supply Chain.

There is the Physical Supply Chain consisting of infrastructure, assets, and people (e.g., trucks, trailers, roads, ports, containers, chassis, warehouses, drivers, warehouse workers). There is also the Digital Supply Chain, which involves connecting trading partners electronically to share real-time data, documents, and information with each other and leveraging software applications to enable smarter and more automated transactions and business processes.

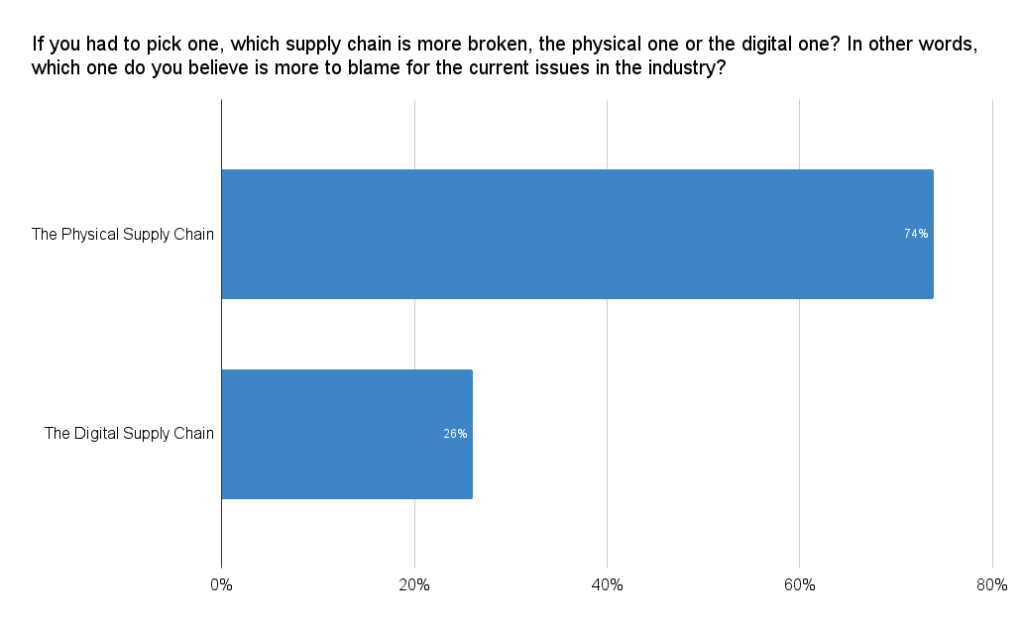

If you had to pick one, which supply chain is more broken — the physical one or the digital one? In other words, which one is more to blame for the current issues in the industry?

We asked members of our Indago supply chain research community — who are all supply chain and logistics professionals from manufacturing, retail, and distribution companies — that question in October 2021. Almost three quarters of our survey respondents (74%) believe the Physical Supply Chain is more to blame for the current issues in the industry.

A supply chain executive member summed it up this way: “I believe the digital has brought to light the challenges in the physical supply chain.”

Overall, “Ocean ports” topped the list of physical supply chain components that are most broken or need the most fixing, with 74% of the survey respondents selecting it. (Indago members can download the full results at our website).

As I wrote a few weeks ago, companies often make the mistake of viewing technology as a silver bullet solution to their supply chain problems, but there are no silver bullets, especially when it comes to enabling true end-to-end supply chain visibility, or to solving issues related to the physical supply chain.

The bottom line for me: until we start investing more to improve and expand the physical supply chain, the overall benefits of supply chain technology will remain constrained.

What do you think? How would you respond to Kevin’s question? Post a comment and share your perspective.

Also, for related commentary, please read “Beyond Digital: The Physical Transformation Of Supply Chain Distribution Networks” and “What We Need (More Of) Now In Logistics.”