Last-mile and home delivery has emerged as a competitive battleground for many retailers and other companies, thanks in large part to the ongoing growth of e-commerce and the likes of Amazon who are reshaping consumer expectations for faster (trending toward same-day) and less expensive (usually free) delivery options.

While home/last-mile delivery is not new, the operating environment is becoming more dynamic and complex, which is making profitable execution even more challenging. It’s also leading to new delivery models and competitors emerging (see, for example, Walmart’s recent announcement that it partnering with Uber, Lyft, and Deliv to test home delivery of groceries and general merchandise in select cities).

Compared to the United States, the home/last-mile delivery market is arguably more mature and advanced in Europe, especially in the United Kingdom. Therefore, I took a trip across the pond a few weeks ago to gain some additional knowledge and perspective on this market. I met with executives from Paragon Software Systems, a provider of truck routing and scheduling and home delivery solutions, with more than 30 years of experience serving the needs of clients across Europe and the U.S. I also had the opportunity to meet with executives from Martin Brower, Dreams, and Warburtons to learn more about their delivery operations, the challenges and opportunities they face, and how technology is helping them.

Today, I’ll share my takeaways from my visit with Paragon (an Adelante SCM client) and my conversation with Peter Holdsworth, Head of Scheduling, UK and Ireland at Martin Brower. In a future post, I’ll share my takeaways from the other customer interviews.

Paragon Software Systems Briefing and Demos

Last September, Paragon opened its new Technology Center at its Head Office in Dorking in the UK, which the company uses for product demonstrations, testing, one-to-one training and business reviews with clients. This is where I met with William Salter, President & CEO of Paragon, along with other executives from the company for a deep-dive briefing about the company and its solutions. It’s impossible to summarize a full day of presentations, product demos, and conversations in a brief blog post, but I’ll share some of the highlights.

First, as mentioned earlier, Paragon has been developing truck routing and scheduling solutions for more than 30 years, and it continues to invest about 33% of revenues into research and development — a relatively large percentage compared to most software vendors. Also, the core development team has been together for many years, something the clients I spoke with greatly value. Simply put, they view Paragon as a partner that not only provides them with capable software, but also provides them a wealth of knowledge and experience to solve new challenges and requirements as they emerge.

Unlike other transportation management system (TMS) vendors that have opted to go broad with their solution footprint, Paragon has opted to go deep in solving the ever-changing routing and scheduling and home delivery needs of clients in a diverse set of industries: supermarkets, food service, beverage distribution, industrial gases, third-party logistics providers, and others. As you would expect, no two companies or industries are alike when it comes to their distribution networks, business rules, and constraints. The team at Paragon walked me through various use cases, from the relatively simple (a few trucks routed from a single distribution center) to the very complex, including the ability to schedule fleets at multiple distribution centers as a single shared resource.

From a software architecture standpoint, Paragon is able to address all of these routing and scheduling requirements using the same code — that is, instead of creating different software products for different industries, the core solution and underlying algorithms are highly configurable to meet the specific needs of each client. If custom development is required, the new capabilities are rolled into the core product moving forward.

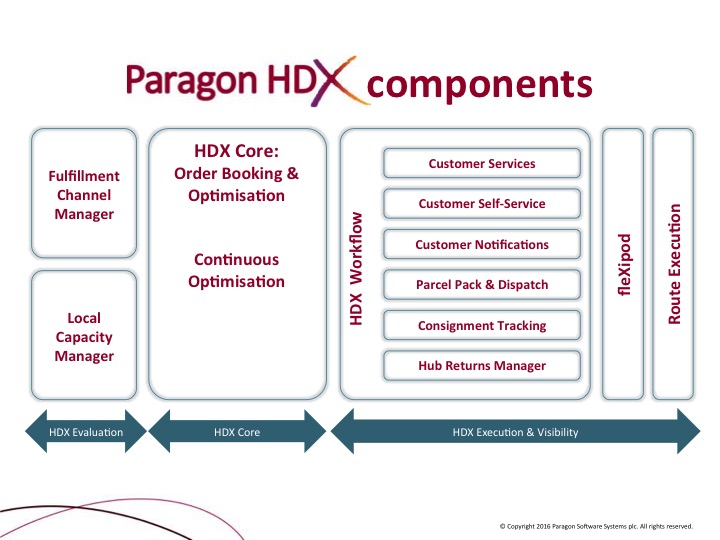

One of the benefits of meeting at the Technology Center is that I was able to get a thorough demonstration of Paragon’s home delivery solution called Paragon HDX, used by clients such as Argos, Dreams, Wickes, Wincanton, Indesit and IKEA. The slide below provides a high-level overview of the solution components.

What impressed me the most was the breadth of the solution. As I expected, it includes dynamic and continuous optimization capabilities, as well as the ability for consumers to select delivery dates and times at the point of sale. But it also includes functionality I didn’t expect, such as Parcel Pack and Dispatch and a business rule engine called Fulfillment Channel Manager that evaluates and determines upfront the best delivery options for an order. In short, Paragon HDX aims to address the full end-to-end home delivery process, from omni-channel order capture through returns management and reporting, but customers have the ability to deploy only the modules they want or need at the moment.

I was also impressed by the fleXipod module, a mobile proof of delivery and fulfillment system the company introduced in May 2015. As described in the press release:

fleXipod is an electronic proof of delivery system that can be implemented using PDA, tablet, and smartphone devices. In addition to traditional electronic proof of delivery functionality, fleXipod enables users to create, manage, deploy and utilize fully configurable data capture forms allowing users to change the driver “workflow” to meet a variety of business requirements. As well as standard required actions following specific task outcomes – signature on screen following successful delivery, additional note capture regarding a damaged installation part, photograph of premises if end client not present and so on – the forms management module allows a further level of data to be captured with the specific details completely under user control.

Although most of Paragon’s clients are in Europe (its solutions are deployed in 1,000 customer sites in 59 countries), the company has operated in the United States since 2004, where it currently has over 100 clients. The company continues to expand its team in the U.S. to support growing customer demand here. Paragon also opened an office in Shanghai, China this past February. The company operates there as a Wholly Foreign Owned Enterprise (WFOE), allowing it to employ its own staff and enter into contracts directly with customers.

In summary, considering all of the mergers and acquisitions that have occurred in the logistics software industry, as well as all of the startups that have come and gone, it’s rare to find a software company like Paragon that has stayed the course in developing routing and scheduling solutions for over 30 years, a segment of the market that is finally getting its day in the spotlight.

Interview with Peter Holdsworth from Martin Brower

Martin Brower’s mission is to be “the leading logistics service provider for restaurant chains around the world, creating an outstanding work environment for our employees and delivering unmatched value for our customers while protecting their brands.” The company has over 60 distribution centers in 18 countries around the world.

Peter Holdsworth is the Head of Scheduling for the UK and Ireland at Martin Brower, where he oversees more than 250,000 deliveries annually to customers in those countries.

I had a chance to interview Mr. Holdsworth at the Paragon Technology Center and I asked him about the biggest challenges facing the industry today. In addition to more intense competition and increased traffic congestion, he talked about customer expectations becoming more demanding.

“Customers today require a higher level of service,” said Holdsworth. “Whereas in the past perhaps you could have gotten away with a morning or afternoon delivery, customers don’t want that today. They want an absolute delivery time, and not only that, if you give them an absolute delivery time of 8:00 am, they expect you to be there at 8:00 am…So, you have to get to the customer on time while [dealing with more traffic congestion and complying with new and ever-changing CO2 emissions regulations] at the same time.”

So, how is technology helping Martin Brower address these challenges? Watch the short video clip below where Holdsworth discusses the various solutions they use to manage their fleet operations.

My key takeaway is the importance of having a closed-loop planning and execution system — that is, the ability to feed actual performance data from vehicle tracking systems, driver feedback, and other sources back into the routing and scheduling system so that the plans produced reflect current operating realities.

So, why did Martin Brower select Paragon as a technology partner? Holdsworth provides his answer in the clip below:

“One of the things you have to consider is the longevity of a product,” Holdsworth said. “You can buy a product that is good and may even be [tops in the market] today, but where will it be in 10 years or 20 years?…Paragon is in a state of perpetual development and I don’t see [that ending].”

I encourage you to watch my full interview with Peter Holdsworth for additional insights and advice on this topic.