Over the past few weeks, there’s been a lot of buzz and discussion about Amazon’s acquisition of Whole Foods, everything from the impact to competing grocery retailers and prices to the accelerated evolution of omni-channel distribution. I was particularly interested in this deal because the grocery industry is near and dear to my heart. My dad and uncles owned a bodega in Brooklyn, NY, where I worked many summers as a kid and teenager stocking shelves and delivering groceries. It is also my go-to example when I try to explain supply chain and logistics to my kids. “Do you ever wonder how all of these foods and products got here,” I ask them. “How does the store know how much to order? Why doesn’t the ice cream melt when it gets transported from the factory? Can a single truck deliver multiple types of products together, like cereal and meat, or do they come via separate trucks? How often does a store get a delivery? Does one truck deliver to multiple stores or just one?”

The questions are endless and they illustrate the complexities involved with food distribution, especially when you take food safety regulations, perishability, and other factors into consideration too.

Yes, parcel shipping has its own set of challenges and complexities, but I believe food distribution is further up on the complexity scale and it’s something that Amazon now has to contend with at a much larger scale than it has with Amazon Fresh.

Take one of the questions above, for example: Can a single truck deliver multiple types of food products together or do they get delivered via separate trucks? When I worked at the bodega in the late ’70s and mid ‘80s, multiple food distributors visited the store each week: one truck delivered dry goods, another frozen products and meats, and yet another delivered produce. Today, many food distributors and grocery retailers use multi-temperature trailers with different compartments that can hold frozen, refrigerated, and ambient products in a single load. For example, here’s a description from a 2001 profile of Kroger’s food supply chain published by Louisville Business First:

The frozen food portion of the order is assembled at 6:30 a.m. and loaded in the front compartment, or nose, of a multi-temperature trailer where the temperature is 20 degrees below zero.

A special partition, or bulkhead, is closed to protect the product.

Meat and cheese are loaded next and “sealed” at their proper temperature in the second phase.

Produce and flowers are loaded in the final phase. [Craig McGuirk, distribution manager of The Kroger Co.’s Kentucky Distribution Center] explained that the multi-temperature truck keeps costs down by allowing one truck to be used for various products, cutting down the number of trucks needed to deliver an order.

But what if that multi-temperature trailer (MTT) is used to visit multiple stores, or in the case of food distributors, multiple clients? Many of these MTTs have a single unloading/loading door at the back of the trailer, which means, for example, that if you’re delivering ambient, refrigerated, and frozen products to multiple stores or clients, the first store or client has to unload all of the products in the first temperature zone to reach the next temperature zone. In such a scenario, what is the optimal way to load these trailers and route the deliveries?

Routing just a handful of trucks to a few stores or customers in the most optimal manner — that is, in a way that minimizes miles driven and costs while satisfying delivery time windows and other customer constraints — quickly reaches the limit of human capability. When you consider that large grocery retailers and distributors have hundreds or thousands of trucks, along with thousands of pickup and delivery locations, the route optimization problem becomes, well, truly mind-boggling!

Good luck trying to solve this problem using a spreadsheet if you have a large distribution network, especially when you add other factors and constraints into the mix, such as delivery frequency and trailer capacity (e.g., maximum cube or number of pallets) per temperature zone.

To illustrate the broader questions involved, consider the research conducted by Mayurpankhi Barooah and Seung Hwan Shin at MIT (Optimal Multi-Temperature Delivery Frequency for Small Format Stores, June 2015). Here’s an excerpt from their thesis paper:

The purpose of this thesis is to evaluate costs between current delivery practices and new delivery strategy spanning trailer type, delivery frequency and product mix…

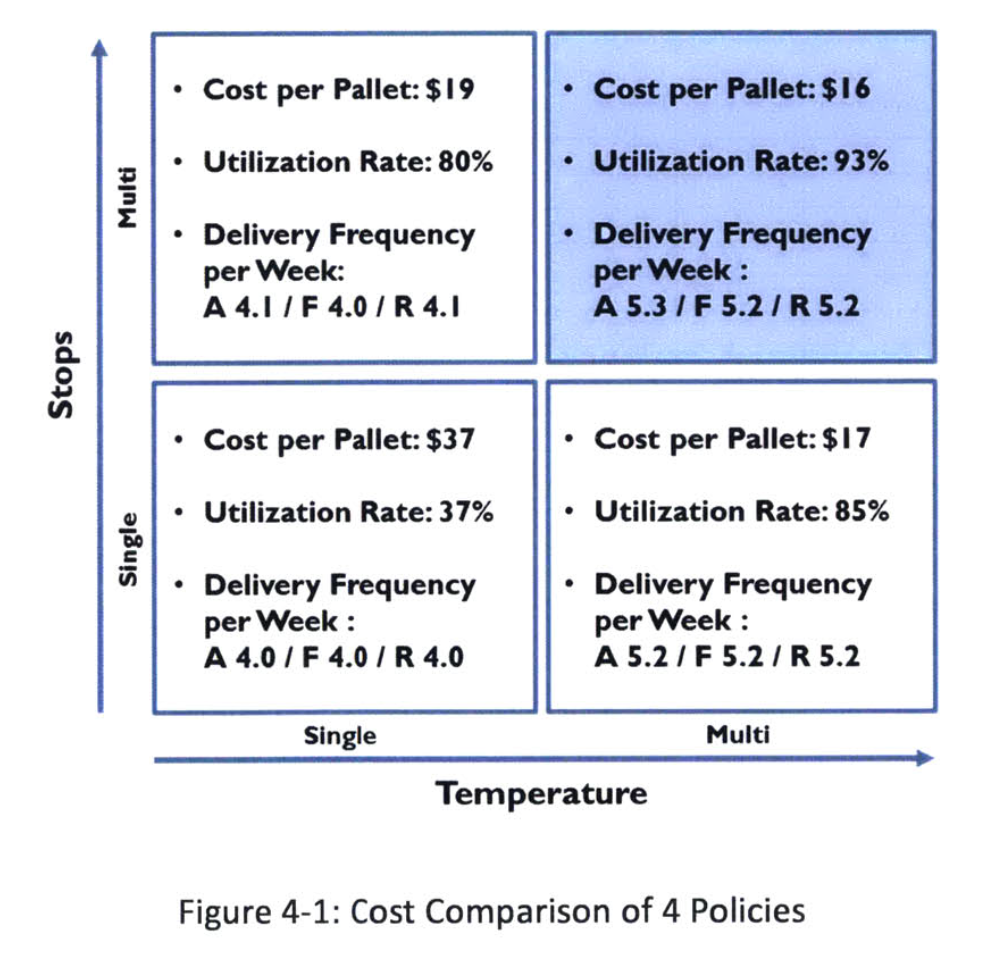

There are two critical variables in our model that together define the various options available to RetailCo while delivering to small format stores: 1) type of trailer: whether single temperature or [multi-temperature trailer] and 2) number of stops: whether single or multiple. In order to structure our analysis, we have organized these options into a matrix, where one axis is type of trailer and the other is the number of stops. The first part of our overall analysis focuses on assessing the four different policies in this matrix by utilizing historical sales and delivery data and determining which policy is most cost-effective. The second part of our analysis is the usage of optimization modeling and simulations on the selected scenarios for further examining feasibility and developing a generic framework for delivery to small format stores.

You can read the thesis for all the details, but it’s sufficient to say that a lot of different data and factors were involved (e.g., cost per pallet, trailer utilization rate, delivery frequency) to come up with the results summarized in the matrix chart below:

“In the case of MSST [Multi-Stop Single Temperature] and MSMT [Multi-Stop Multi-Temperature] options [the] calculation [was] complicated due to the large number of possible routes,” state the researchers. “To identify the combination of route, delivery frequency and delivery quantity that minimizes overall cost for MSST and MSMT, we have used an optimization model formulated and developed by Unahalekhaka based on requirements provided by the authors of this research.”

This case underscores an important point: the more complex supply chains become, the more important optimization becomes, and this is especially true in food distribution, where profit margins are thin and losing customers due to poor service or quality is costly.

“We need the ability to make smarter decisions faster,” is what supply chain executives tell me. They might not realize it, but what they’re really saying is that they need optimization.

The good news is that today’s optimization solutions are not only much more powerful than in the past, they’re also much more user friendly and configurable. The latter point is particularly important because no two distribution operations are the same, and operating realities and constraints are continuously changing too, so optimization solutions must have the ability to take into account all of the unique requirements and constraints of each operation, and make it easy for users to make adjustments as changes occur.

I don’t know which optimization solution Whole Foods uses, but I assume it employs something more sophisticated than spreadsheets and whiteboards. Other leaders in the industry use optimization software from leading third-party vendors. Walmart, for example, uses Quintiq (a Talking Logistics sponsor) “to support logistics load managers at Walmart in assigning loads to driver-truck combinations to create optimal sets of trips, and to dispatch those trips through an on-board computer to the driver,” according to a 2012 press release. “Based on real-time updates from the driver’s on-board computer, Quintiq’s optimization engine continuously re-optimizes the sequence of trips and provides recommendations to logistics load managers through its user interface.”

So, the next time you walk the aisles of your favorite supermarket, stop for a moment and think about all of the complexity involved in getting those cereal boxes on the shelf, deli meats in the refrigerator, bananas on the produce stand, and ice cream in the freezer.

It’s mind-boggling, isn’t it?