The COVID-19 pandemic and its ripple effects have put supply chain risk management back in the spotlight. Simply put, supply chains today face greater risks than in the past, including from relatively new threats like cyberattacks.

How often do you consider risk in your supply chain decisions?

We asked members of our Indago supply chain research community — who are all supply chain and logistics executives from manufacturing, retail, and distribution companies — that question in a January 2023 survey.

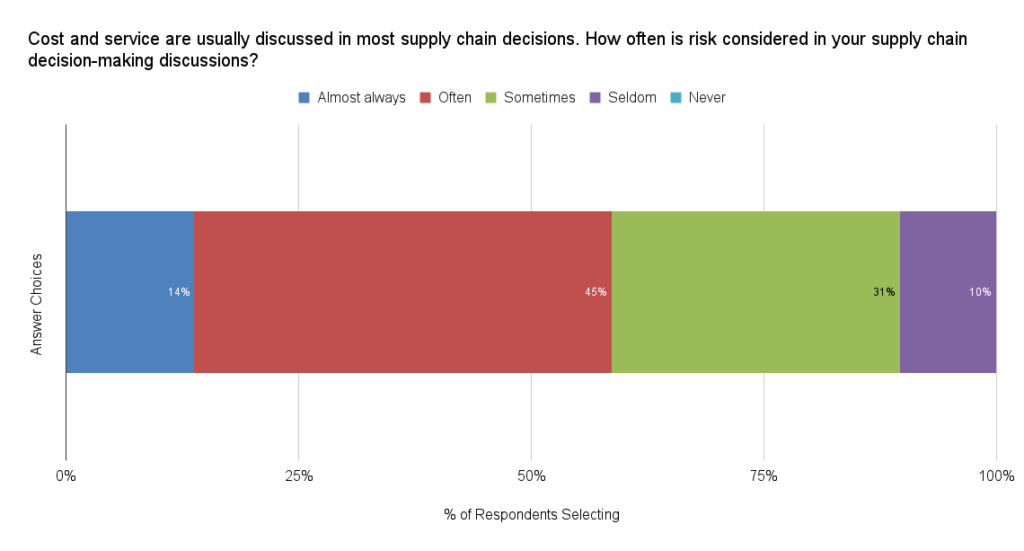

With 41% of the respondents saying they only “Sometimes” or “Seldomly” consider risk in their supply chain decision-making process, and only 41% characterizing their company’s approach to supply chain risk management as “Very Proactive” or “Proactive,” it’s clear that talking and thinking about risk in supply chain management is not yet as common and instinctual as talking and thinking about cost and service.

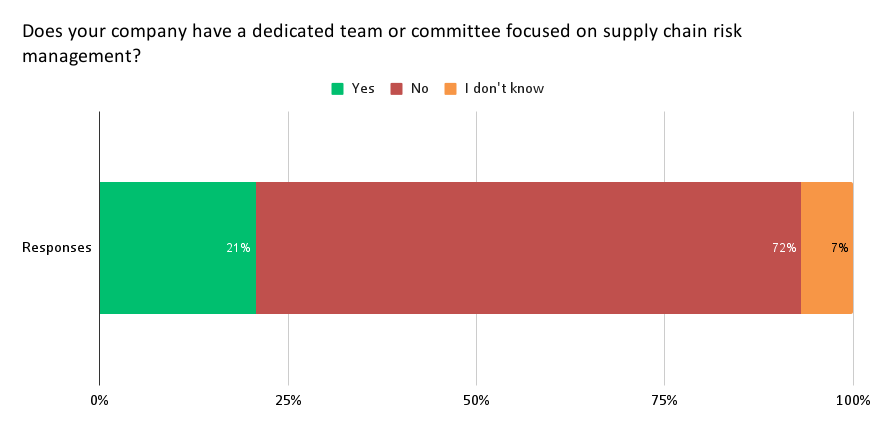

This is reflected organizationally too, with most of the respondents (72%) saying their companies do not have a dedicated team or committee focused on supply chain risk management.

“Without a doubt, the biggest challenge is changing our organization’s mentality from reactive to proactive,” said one Indago supply chain executive. “Our organization is completely reactive with regards to supply chain risk management, without any strategic planning in this area.”

Another executive commented, “Supply Chain Risk is only recognized when a disruption occurs. Sole sourcing is my major concern. I can’t seem to get this driven home. The Texas Freeze two years ago should have taught us then, yet we still sole source too many components.”

“Sadly, Supply Chain Risk Management is not strategic at my company; it’s more of a reaction,” said another executive. “We deal with issues as they occur.”

That said, many companies recognize the role and importance of supply chain risk management, and they’re taking action to reduce and manage risks, as these respondent comments illustrate:

“We have a C-level risk assessment team that is identifying risks and mitigation plans. Our technology team is proactively implementing technology to reduce risk. A huge part of their program revolves around employee training.”

“Our business’ overall strategy for 2023 is to identify risks throughout the business and supply chain, and to mitigate those risks anyway possible. We don’t have software investments planned or slotted to help mitigate those risks; however, we are doing what we can via manual means to tackle these risks.”

“SCRM has become top of mind for most supply chain professionals. Where and how disruptions will occur is hard to predict but effective contingency planning can help mitigate negative impacts. Technology can help in running ‘what if’ scenarios and enabling a rapid response by collecting vast amounts of data on alternatives and optimizing outcomes based on newly established constraints.”

“I am preparing a risk map (and cost and probability analysis) for my function. I am also checking other functional areas that could impact my area. Excel and PowerPoint are enough to do this analysis.”

Which risks are you most concerned about? Is supply chain risk management part of the business case used to invest in technology?

Indago members shared their perspectives on those questions too. Members can download the report at the Indago website.

What actions are you taking (or should take) to improve your supply chain risk management capabilities? Post a comment and share your perspective!

Be Uncommon. Research with Purpose.

If you’re a supply chain or logistics practitioner from a manufacturing, retail, or distribution company — and you’re interested in learning from your peers — I encourage you to learn more about Indago and join our research community. It is confidential, there is no cost to join and the time commitment is minimal (2-4 minutes per week) — plus your participation will help support charitable causes like JDRF, American Logistics Aid Network, American Cancer Society, Feeding America, and Make-A-Wish.