Editor’s Note: The following is an excerpt of a research report published recently, “Generative TMS: An Outcome-Driven Approach to Selecting and Deploying a Transportation Management System.” The research, conducted by Adelante SCM and commissioned by Alpega, highlights how modern technologies are enabling companies to customize Transportation Management Systems (TMS) to meet their unique needs and drive specific outcomes. The report includes data and insights from Indago’s supply chain research community and Alpega’s customer community. Please visit the report page to download the full report.

One of the hottest technology topics today, especially since the introduction of ChatGPT in November 2022, is Generative AI. It is a type of artificial intelligence that can create new content, such as text, images, music, or even software code.

Yes, generative AI tools can code.

“New [generative AI] tools are rapidly emerging that offer code suggestions and even write entire code,” writes Bernard Marr in a June 2024 Forbes article. “And it can all be done based on natural language prompts or by learning from existing code.”

Is the software these tools develop any good? As Marr reports, “When the Alphabet-owned DeepMind lab pitted its AlphaCode AI model in competition against human coders, AlphaCode’s performance roughly corresponded to ‘a novice programmer with a few months to a year of training.’ It’s not bad at all for an AI. Given that generative AI’s capabilities are progressing so fast, we can expect the technology to catch up with more experienced developers in the not-so-distant future.”

Let’s imagine a future where a generative AI tool exists that can “generate” a tailored Transportation Management System (TMS) based on the input provided by a user. What input would you provide such a tool for it to generate a TMS that meets your needs and performance objectives?

To answer this question, you first have to answer a different question: Why do you want to implement TMS?

The truth is that most companies don’t really want to buy a TMS; they want to buy outcomes — that is, they want to reduce transportation costs, improve service levels, increase productivity, reduce CO2 emissions, obtain real-time visibility, improve customer satisfaction, and so on. As Harvard marketing professor Theodore Levitt famously said, “People don’t want to buy a quarter-inch drill; they want a quarter-inch hole!”

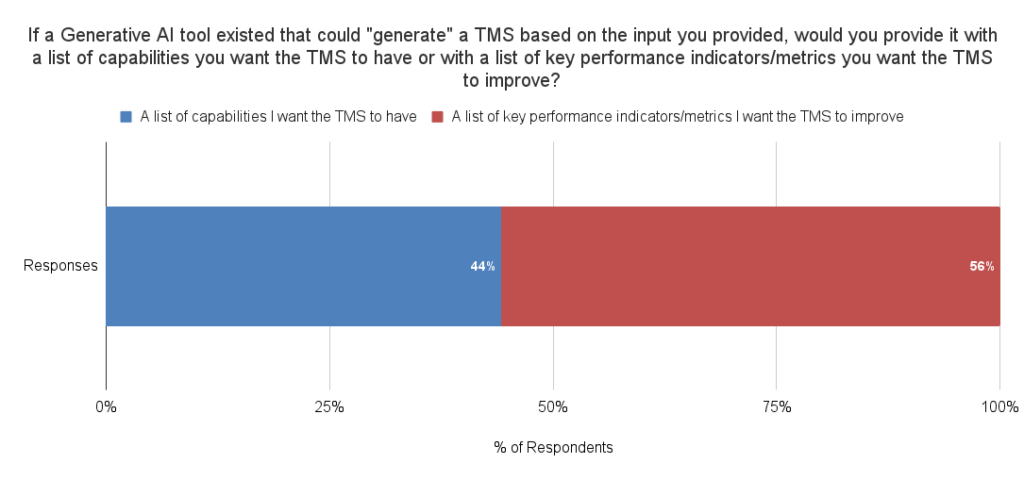

This is supported by a July 2024 survey conducted with members of Indago’s supply chain research community, who are all supply chain and logistics executives from manufacturing, retail, and distribution companies, and with members of Alpega’s customer community. More than half the survey respondents (56%) said that if a generative AI tool existed that could generate a Transportation Management System based on the input a user provided, and they could only provide one type of input, they would provide it with a list of key performance indicators/metrics they want to improve.

Source: July 2024 Indago survey of 43 qualified and verified supply chain and logistics executives from manufacturing, retail, and distribution companies.

In practice, however, companies spend more time and effort developing a long list of functional requirements, which they send to TMS vendors as a Request for Proposal (RFP), than they do in clearly defining their desired outcomes and how to measure success. This is one of the reasons why many companies experience “buyer’s remorse” with IT purchases.

Back to the hypothetical Generative AI tool: If you were to provide such a tool a list of transportation key performance indicators (KPIs) you want to improve, which ones would you provide (are the most important) to meet your objectives?

According to the July 2024 survey of Indago members and Alpega customers, “On-Time In-Full (OTIF)” topped the list of KPIs, with 60% of the respondents selecting it.

In recent years, On-Time In-Full has become critically important for companies in the Consumer Packaged Goods (CPG) and Retail industries. Walmart, for example, first instituted OTIF requirements in 2017, then tightened them further in late 2020, requiring suppliers to deliver shipments on time and in full 98% of the time. Suppliers unable to meet this rule faced fines of 3% of the cost of goods. In February 2024, as reported by The Wall Street Journal, “Walmart [eased] its requirements for on-time and in-full shipments from its suppliers. The retailer [now] wants suppliers to deliver shipments on time 90% of the time and in full 95% of the time.” The fine for non-compliance, however, remains the same.

While this change is welcomed by suppliers, the new requirements are still challenging to meet. This is especially true if you lack important TMS capabilities, such as load optimization, route optimization, and real-time freight visibility.

It’s also important to note, as highlighted in a June 2019 McKinsey article, that “there is no standard definition for OTIF, so different supply-chain participants may interpret the metric in significantly different ways. Does ‘on-time’ mean on the date requested by the retailer, or the date promised by the manufacturer? Does it mean within the specific delivery slot allocated to the shipment, or any time inside a broader, agreed-upon time window? Should ‘in-full’ be measured at the level of complete orders, line-items or individual cases?”

Therefore, it’s important for all stakeholders to “develop a standard definition of OTIF as well as [adopt] a standard approach to calculate, report, and manage OTIF.”

What other KPIs did the survey respondents prioritize? What TMS capabilities are they looking for the most? For insights on those questions and more, please download the research report.