In June 2024, Amazon announced “its largest reduction in plastic packaging in North America to date.” This is the latest example of how improving packaging can lead to benefits for transportation and warehousing operations.

Has your company made any packaging changes that improved transportation or warehousing operations?

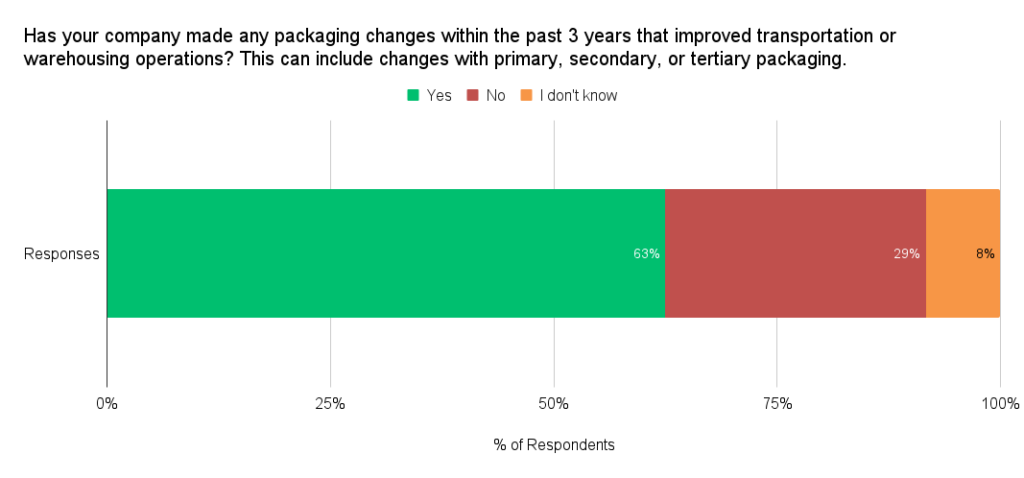

We asked that question last July to members of our Indago supply chain research community, who are all supply chain and logistics executives from manufacturing, retail, and distribution companies. Close to two thirds of the respondents (63%) said that they had made packaging changes within the past 3 years that had improved transportation and/or warehousing operations.

“We made changes to our product that would allow us to change the packaging to [use] a smaller box,” said one logistics executive. “It went from a single box on a pallet to now being able to put 6 boxes on a pallet.”

Here are some other comments submitted by our Indago members:

“We made packaging changes to support automation in our warehouses and to improve overhang of product on pallets.”

“A lot of our packaging is dictated to us by our main supplier. The fragility of our products is also a big barrier to streamlining packaging as it exposes our orders to potential damage while in transit. All that said, we are always looking for ways to minimize and streamline packaging if the integrity of the delivered order/product won’t be compromised.”

“My company makes medical devices, which need to be unpacked and go directly into use. That said, a lot of our devices are packaged with a good amount of air in the packaging. By changing the way our products are constructed (e.g., foldable) we can reduce the air inside our packages and fit significantly more on a pallet and in a trailer. This has been done in partnership with our R&D and Supply Chain teams.”

“Our logistics team collaborates very closely with product and package design to ensure product packaging is economical, sustainable and works well within our warehouse automation and other processes.”

“You can easily cut pennies in packaging costs but incur increased dollars in damage, handling, safety, and quality.”

We also asked our Indago members, “How would you characterize the opportunity that exists at your company to realize transportation or warehousing benefits if changes were made to product and/or packaging designs? What do you see as the biggest potential benefits?”

For insights on those questions and more, Indago members can download the report at our website.

How about you? Does your logistics team collaborate with your product and packaging designers to factor in logistics considerations into their designs? Have you had any success in enabling logistics benefits via improved product/packaging design?

Post a comment and share your perspective and experience on this topic!

The Road to 1,000 Indago Members

This coming March will mark 6 years since we launched Indago. Our goal is to reach 1,000 members by the end of 2025 — and to break the $30,000 mark in charity donations since we launched.

Why join Indago? Here’s how a couple of our members answered that question:

“Joining Indago has been great. On a monthly basis I complete an easy, 5 minute survey about important topics in Supply Chain (I often complete the survey on my smartphone). I find value in completing the survey; it gives me a reason to spend a moment defining my perspective on strategic topics. In return, I am able to see the results of the survey and the perspectives of my peers. On a few occasions, I’ve reconsidered my position based on what the community suggests, and other times, I’m happy to see the validation of my views (especially on topics that have been overhyped in the trade journals). Because the surveys are anonymous, it’s a risk free way to engage the Supply Chain community and get quick, honest feedback.” — VP of Operations, Food & Beverage Company

“I decided to join Indago for two reasons. One is to be part of a group that provides real time feedback from companies on topics in the supply chain world. The second reason is that Indago supports charities that make the world a better place. It’s a great one – two combination!” — Director of Freight & Warehousing, $1B+ Food & Beverage Company

So, what are you waiting for? Find out what you’ve been missing and join Indago today!

If you’re a supply chain or logistics practitioner from a MANUFACTURING, RETAIL, or DISTRIBUTION company and you’re interested in learning from your peers, I encourage you to learn more about Indago and join our research community. It is confidential, there is no cost to join and the time commitment is minimal (2-4 minutes per week) — plus your participation will help support charitable causes like Breakthrough T1D, American Logistics Aid Network, American Cancer Society, Feeding America, and Make-A-Wish.

(If you’re a TECHNOLOGY VENDOR or THIRD-PARTY LOGISTICS COMPANY, please do not apply. If you’re interested in receiving our research results and contributing questions for us to ask our members, we have a subscription service available. Please contact me for additional information.)