In the post Hidden Suppliers Can Make or Break Your Operations (Harvard Business Review, May 2015), the authors write, “With the size and complexity of supply chains soaring, a daunting challenge is confronting companies: identifying the critical nodes hidden within the vast expanse of their supply networks.”

The coronavirus outbreak has put supply chain risk management (SCRM) back in the spotlight. A key component of SCRM is supply chain mapping – i.e., knowing where the manufacturing/production facilities of your suppliers (and their suppliers) are physically located, and which parts or materials are manufactured/produced at each location.

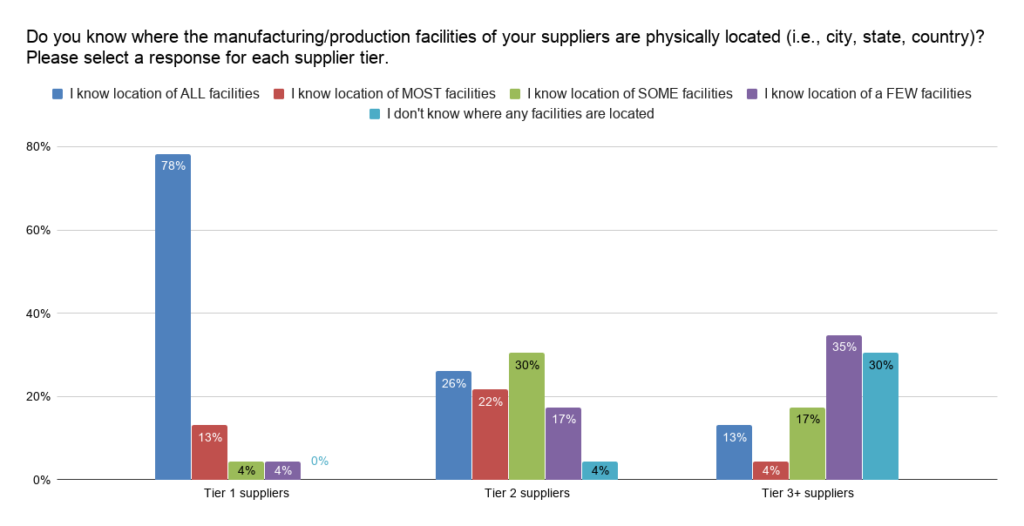

Earlier this year, we asked our Indago members about their supply chain mapping experience and capabilities. As expected, our members have the most visibility to the physical locations of their Tier 1 supplier facilities, with 91% saying they know where ALL or MOST of them are located. In contrast, only 17% said they know where ALL or MOST of their Tier 3 supplier facilities are located.

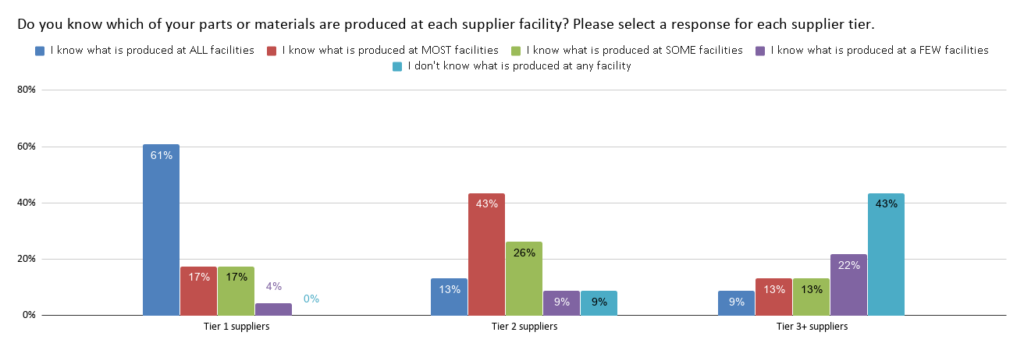

Similarly, when it comes to knowing which parts or materials are produced at each supplier facility, the best visibility is with Tier 1 suppliers (61% know what is produced at ALL Tier 1 facilities compared to just 9% that know what is produced at ALL Tier 3 facilities).

Here are some value-added comments from our Indago members, who are all supply chain and logistics professionals from manufacturing, retail, and distribution companies:

“We know precisely where our local suppliers are located and the countries of the next supplier upstream. Suppliers further upstream are rarely known with certainty. We have not engaged in any mapping exercises to date. Unfortunately, most of the supplier locations in our ERP are office addresses and often not the location where product is actually manufactured or sourced.”

“Very challenging if there is not a rigorous reporting structure. It is very challenging to have a fully comprehensive list of Tier 3 [suppliers] and beyond, even for only physical locations that can be impacted by global events. Financial standing is another major concern.”

“Our industry is pretty vertical so it’s easy to know what’s being produced at our Tier 1 suppliers, but [further upstream] things get a bit murky when you start looking at raw goods suppliers.”

“Over a decade ago, we made the decision to concentrate our supplier base and become meaningful to each supplier. To mitigate our risk, we became actively involved in every aspect of our suppliers’ business (including plant layout, subcontractors, fire suppression, staff training, logistics, etc.). It was (and still is today) our intention to truly ‘partner’ with our suppliers. While we do not have an actual cash investment in our suppliers, we do have a vested interest in producing our product ‘on time, on quality and on cost.’ What was to be a three-week trip for me to Asia became a decade long investment (full time in Asia). The results have exceeded our expectations. The biggest challenge is ‘time’ — time to get the trust of your partners to [change] their ‘way of doing things.’ The time invested will pay off significantly. Just remember to be up front, be honest, and do what you say and say what you do.”

What is your experience or perspective with regards to supply chain mapping? How far along is your company in mapping its supply chain? What are the biggest challenges to overcome? Post a comment and share your perspective!

For related commentary, please read Honeywell Investigated For Import/Export Controls: Why Supply Chain Mapping Matters.

Join Indago

Also, If you’re a supply chain or logistics practitioner from a manufacturing, retail, or distribution company, I encourage you to learn more about Indago and join our research community. It is confidential, there is no cost to join and the time commitment is minimal (2-5 minutes per week) — plus your participation will help support charitable causes like JDRF, American Logistics Aid Network, American Cancer Society, Feeding America, and Make-A-Wish.

You can also follow us on LinkedIn to stay informed of our latest research results and news.