I haven’t attended an industry conference over the past year, or participated in a client meeting, where blockchain — along with artificial intelligence (AI) and machine learning — hasn’t been part of the conversation. In fact, at one conference this spring, after delivering a keynote presentation that had nothing to do with technology, the very first question I received from the audience was “What do you think about blockchain and its potential in supply chain management?”

Of course, the most common question about blockchain is “What is it?” but once you get past defining it, more important questions follow:

- What’s real today and what’s hype?

- What happens to my existing technology? Do I have to rip and replace what I have already invested in?

- How do I get started?

Those same questions also come up for AI and machine learning, which is why they took center stage at the IBM Watson Supply Chain Summit last month in Atlanta, GA.

IBM Watson Supply Chain Summit

This invite-only event brought together supply chain and IT executives from a cross section of companies, along with several executives from IBM, including Jeanette Barlow, Vice President of IBM Supply Chain Solutions, and Ron Castro, Chief Supply Chain Officer at IBM.

Ms. Barlow kicked off the summit by highlighting the various challenges that supply chain executives face today — everything from omni-channel fulfillment to dealing with disruptions — and how competing on customer experience is becoming the new battleground. She also discussed how companies “despite their best efforts, are still surrounded by silos in processes and IT,” and how “they have the most data they’ve ever had, but the least amount of insights.”

“We have to reinvent the way we do business in order to stay relevant and competitive,” Ms. Barlow concluded, echoing a similar point I made last year in Unlearning Supply Chain Management.

Ms. Barlow then moderated a panel discussion with me and Paul Gonzalez, IT Manager – Database Administration at Niagara Bottling, a current IBM customer. Mr. Gonzalez (no relation to me, although I joked on the panel that we share the same barber) spoke about Niagara Bottling’s rapid growth and the challenges it creates for IT, particularly when it comes to business-to-business (B2B) connectivity and keeping up with the growing volume of data and information that gets exchanged between trading partners.

Ms. Barlow then asked me the “What happens to my existing technology?” question. Does AI, blockchain, and machine learning extend existing investments or replace them? My short answer was that these newer technologies have to extend existing investments, otherwise this journey will never get started. It would be like building a new highway, but saying existing cars can’t drive on it — you’ll have an empty highway for a long time.

Take EDI, for example. While the trend today is to leverage APIs and web services for B2B connectivity, the reality is that EDI is still very widely used across all industries, and companies are not going to rip and replace those systems overnight. The question then becomes how do you bridge the gap — that is, how do you modernize EDI so that the data and information contained in those messages are more easily accessible, searchable, and contextualized?

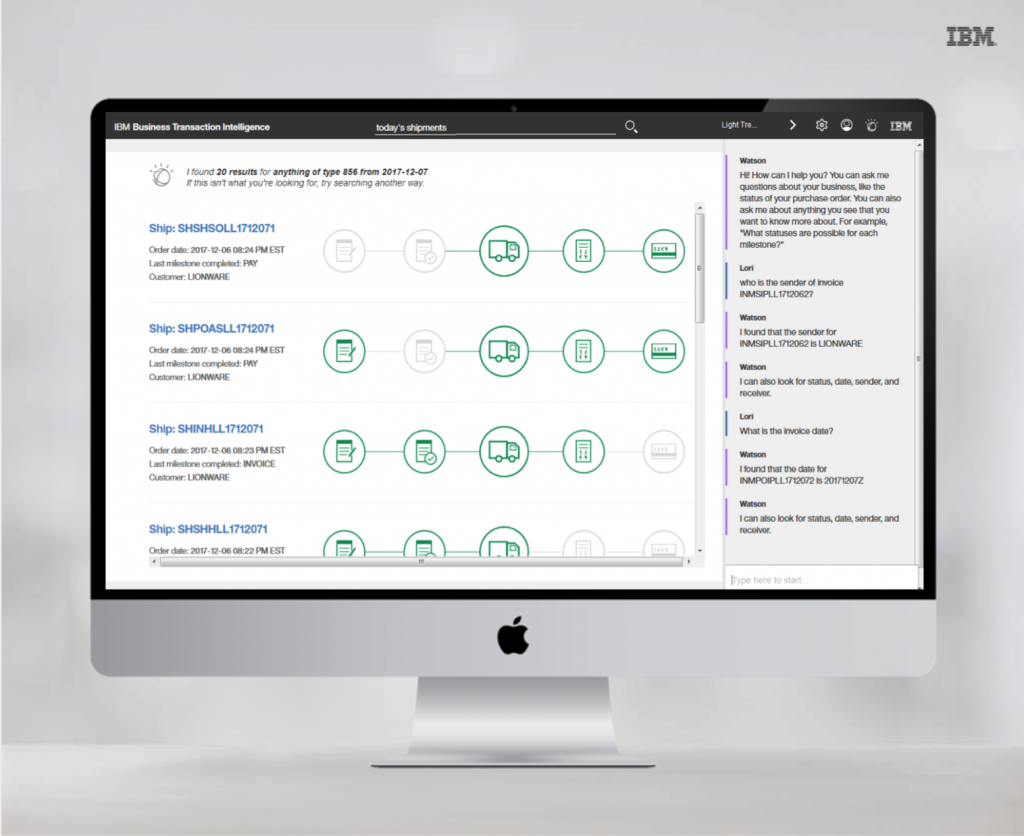

This is an area that IBM has been working on as part of its IBM Supply Chain Business Network, which has about 435K business partner relationships. Specifically, the company has developed Business Transaction Intelligence, which IBM describes as “an AI capability of Supply Chain Business Network that provides meaningful information and insights to help companies better manage order to cash and purchase to pay interactions.”

Think of it as a business intelligence dashboard for the business user that displays information gathered from EDI transactions in the context of the Order-to-Cash or Procure-to-Pay process. It’s also integrated with Watson (here’s where AI comes in), enabling users to perform natural language queries. See the screenshot below showing user Lori “conversing” with Watson to find information about an invoice.

Mr. Gonzalez from Niagara Bottling talked about the opportunities he see with Business Transaction Intelligence, such as enabling greater self-service for business users.

I wrapped up my comments on the panel with the following advice for the attendees:

- Stay informed. Blockchain, AI, and machine learning are evolving very quickly, so keep a pulse on what’s happening. The more informed you are, the better prepared you’ll be to take action when the time comes.

- Don’t be quick to dismiss these technologies. History has shown that saying “It will never work” or “Not in my lifetime” without first doing your homework or staying informed of new developments can cause you to fall behind the competition.

- Don’t fall in love with technology for technology’s sake. The biggest mistake you can make is becoming too enamored with the next new shiny technology and start investing in it without first identifying or understanding the business problem or opportunity you want to address. The first step is to clearly define what you want to accomplish, verify that your existing technologies aren’t capable of meeting your objectives, and then explain how these new technologies can potentially get the job done.

- Identify the right people within your organization to lead the change. The right people are those willing to question the status quo and willing to invest their time and energy to identify, plan, and execute appropriate projects (relatively quick, inexpensive, and low risk) to demonstrate business value.

- Find the right technology partners to help you innovate. Alignment of objectives, culture, and investment priorities are particularly important.

IBM Case Study: Supply Chain Intelligence, Watson, and Resolution Rooms

One of the highlights from the summit was Ron Castro’s presentation about IBM’s journey toward creating an AI powered Supply Chain. In a recent LinkedIn post, Castro summarized what he presented at the summit:

For IBM, supply disruptions, exacerbated by dark data, created an urgency for a solution that could bring greater visibility and orchestration. We wanted to better understand and meet the supply-demand balance, as well as bring people together with the intelligence and capabilities to respond to disruptions and events quickly.

With the business environment and the pressure supply chain professionals are in — complex environment, demanding customers, expectation of speed and agility — IBM decided to look at the combination of machine intelligence and humans and how it can revolutionize our approach. These 4 pillars were critical elements for IBM’s supply chain initiative and set the stage for development of IBM Supply Chain Insights:

-

Proactively get smart alert to predict upcoming disruptive events.

-

Connect structured and unstructured data to analyze and get deep insights.

-

Use collaborative platform to identify solutions and respond to events quickly.

-

Continuous AI learning builds a comprehensive institutional knowledge body.

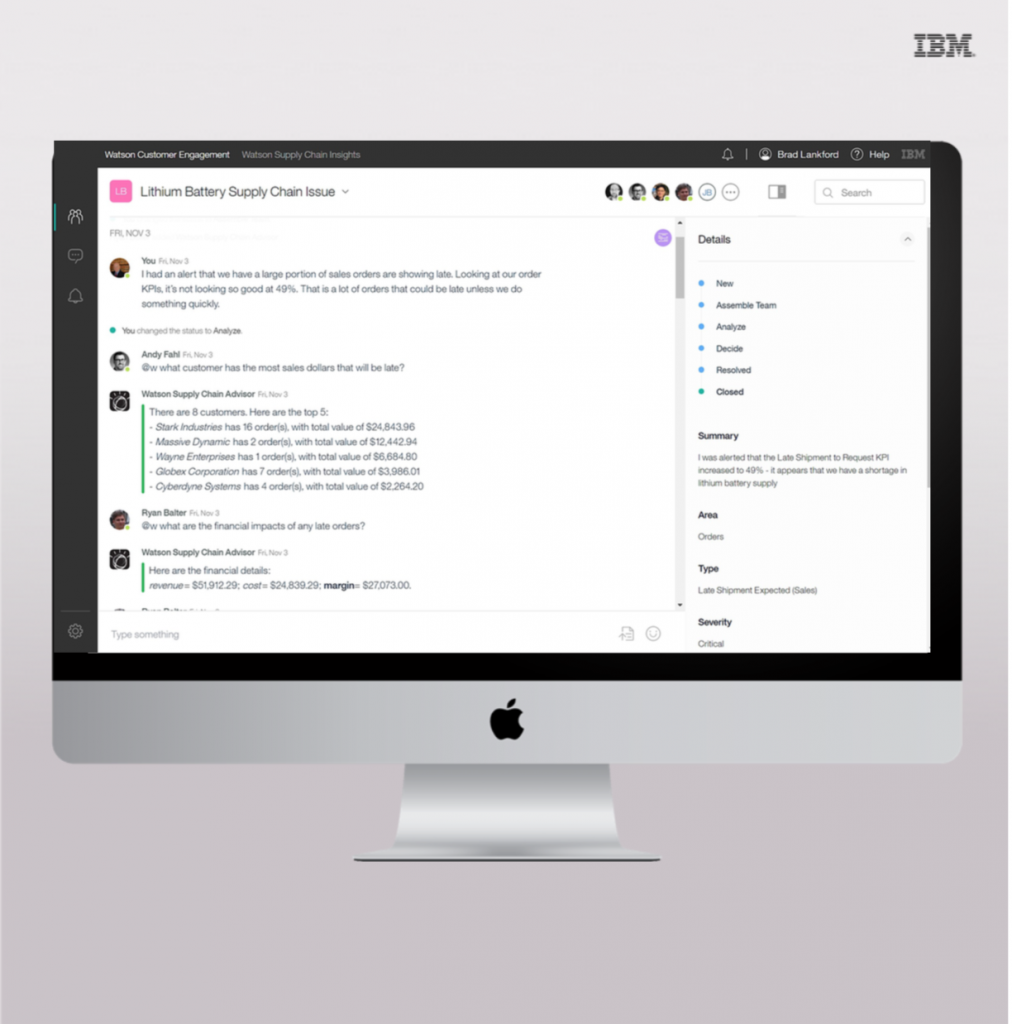

Simply put, IBM Supply Chain Insights is a supply chain visibility platform with predictive capabilities that aggregates and analyzes data from multiple sources — including weather data from IBM’s The Weather Company and other third-party data partners — to identify potential supply chain disruptions and facilitate/expedite their resolution.

The feature that caught my attention the most, however, was Resolution Rooms. Think of them as online discussion groups where team members gather to discuss and resolve supply chain disruptions when or before they arise. Watson is included as a member of a Resolution Room and it can even recommend other experts that should be invited to participate in the discussion based on their knowledge, experience, and/or past contribution in resolving a similar issue. Watson also builds digital playbooks that documents and learns the actions taken in a particular case, and when a similar disruption or issue occurs in the future, Watson can make recommendations based on accumulated knowledge in those playbooks.

In short, I’ve said for a long time that companies will find opportunities for supply chain innovation at the intersection of Software, B2B Connectivity, and Social Networking, with the latter facilitating communication and collaboration between supply chain and logistics professionals — the people side of supply chain management.

Historically, when supply chain disruptions or problems have occured, the typical response is to send an email with attachments to countless people on a cc list (who sometimes reply to all, and sometimes don’t), or to gather people in a conference room for an “all hands on deck” meeting, even though half your employees (who might know the solution) reside six time zones away. I’ve long argued that social networking tools are the most effective communication and collaboration tools in situations where many people, across multiple groups and companies, and across different time zones and geographies, need to communicate and collaborate. Resolution Rooms, enhanced with Watson’s AI and machine learning capabilities, are a perfect example of this in action.

Castro shared some early results that IBM has achieved using this platform:

- Disruptions management down from 18+ days to just hours

- 52% reduction in expedite costs

- 18% reduction in inventory levels

- Late orders reduced by 75%

Wrapping Up

There were other informative sessions during the summit that I don’t have the time or space to summarize here, but my overall takeaway is that the pace of innovation around these emerging supply chain technologies is accelerating, with machine learning and AI leading the way and already demonstrating value. That said, we’re still in the early stages of what’s possible and companies are still having a hard time separating what’s real from the hype and understanding how these new technologies fit within their existing IT investments, so a lot more education is required — and proof points from early adopters.