I’m back from almost 4 weeks on the road.

That is 3 weeks and 4 days longer than the U.S. East Coast Ports strike lasted (although, as I highlight below, the strike has only been paused until January 2025).

Where have I been? I was in Phoenix, Arizona for The Logistics & Supply Chain Forum. From there I went to Vienna, Austria for Transporeon Summit. And this week I was in Chicago, IL for Descartes’ Innovation Forum. I spoke at each of these events, attended many informative sessions, and had some great conversations with supply chain and logistics executives. I will share my learnings and takeaways in future posts and reports.

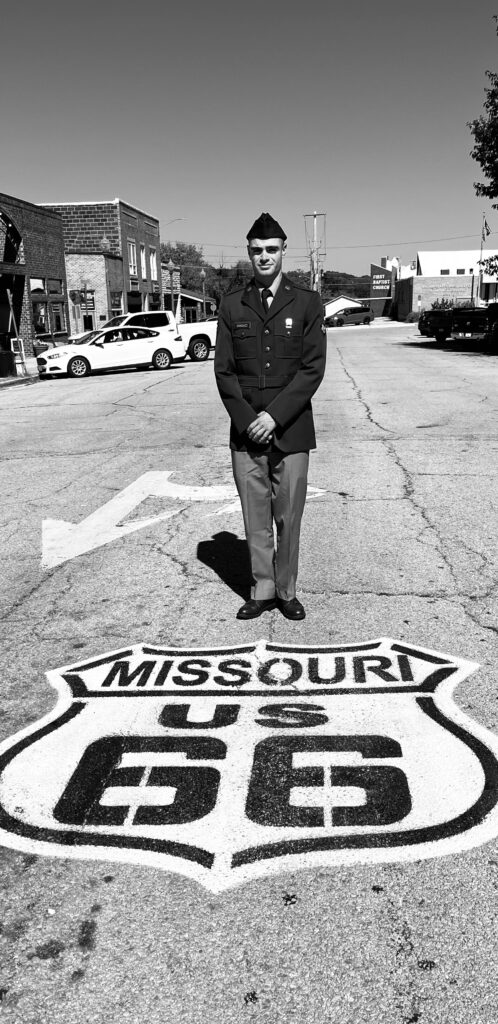

My favorite trip, however, was last week to Fort Leonard Wood, Missouri, near historic Route 66. I was there for my oldest son’s graduation from Army Basic Training. After 10 challenging weeks, he is now officially a soldier. And as I said I would back in July, I hugged and kissed my son after the graduation ceremony. I said “I love you” and “I’m so proud of you,” and then I stepped back, looked at my boy, the man and soldier he’s become, and said, “Thank you for your service!”

He’s now at Officer Candidate School in Fort Moore, GA where he will be for the next 12 weeks on his journey to becoming a Second Lieutenant in the U.S. Army.

I’m glad to be home, except I still have hundreds of emails to go through. But before I grab my coffee and go through them all, here’s the supply chain and logistics news that caught my attention this week.

- The Battle Over Robots at U.S. Ports Is On (WSJ – sub. req’d)

- Amazon unveils the next generation of fulfillment centers powered by AI and 10 times more robotics

- Amazon tests adding robot warehouses to Whole Foods so shoppers can pick up other orders at checkout (CNBC)

- Robot Orders Down 8% in First Half of 2024

- Amazon’s ex-retail boss Dave Clark launches new startup to solve supply chain ‘Franken-software’ (CNBC)

- GXO Logistics explores sale after receiving takeover interest, source says (Reuters)

- Industrial Construction Plummets as Vacancy Rates Surge

- Porch Pirates Are Stealing AT&T iPhones Delivered by FedEx (WSJ – sub. req’d)

- Cargo theft trends: Motor carrier number manipulation is on the rise (FleetOwner)

- Gradual trade recovery underway despite regional conflicts, policy uncertainty (WTO)

- German economy expected to contract again in 2024, economy minister says (Reuters)

- Mexico Wants to Curb Chinese Imports With Help From U.S. Companies (WSJ – sub. req’d)

Who’s Afraid of Robots and Automation?

Yes, to the dismay of industry journalists and pundits who were expecting several weeks of horror stories to write about, the East Coast Ports strike lasted just 3 days. For example, I had a piece ready to go on how it had been weeks since I last tasted a banana.

But in reality, the strike has been paused until after the election and holiday season. As Paul Berger, Chip Cutter, and Chao Deng report in the Wall Street Journal:

Tens of thousands of dockworkers last week returned to their jobs on East Coast ports after a three-day strike that threatened to snarl trade and hobble the economy. Workers won a 62% pay increase. But a much larger, thornier issue remains—one that’s playing out in other businesses as well, from factories to grocery stores to Hollywood: How much, and how quickly, are humans willing to concede to machines?

The new dockworker agreement extends only until mid-January. [The leader of the International Longshoremen’s Association] opposition to automation of any kind threatens to derail the continuing negotiations over the next three months and push the dockworkers back to the picket lines.

I’ve addressed the need for increased port automation for many years (see “Ready For The Next Port Crisis?” from February 2015). I wrote about it again this past June, under the subheading “The War Against Automation at U.S. Ocean Ports.” Here’s what I wrote at the time:

Whether there is a strike or not, or whether this current fight turns into a war, the end result will be the same as always: America’s biggest and most important ports will remain laggards when it comes to productivity and efficiency, making them key constraints in global supply chains.

The ILA is delaying the inevitable. U.S. ocean ports have to become more productive and efficient, which means more robots and automation. But the battle against it will be long and painful, and we’ll likely see port workers back on the picket lines in January, so don’t delete those horror stories yet from your computers; you might still be able to publish them early next year. And fill up on bananas while you can.

You know who’s not afraid of robots? Amazon, of course.

The company unveiled this week “the next generation of fulfillment centers powered by AI and 10 times more robotics.” Here are some excerpts from the press release:

Located in Shreveport, Louisiana, our next-generation fulfillment center brings together years of innovation under one roof. The site transforms the way we will work and sets a new standard for efficiencies in the industry.

This facility spans five floors and more than 3 million square feet—equivalent to 55 football fields—making it one of Amazon’s largest sites. It will employ 2,500 employees once it’s fully ramped up.

At the center of the facility is Sequoia, a state-of-the-art multilevel containerized inventory system that makes it faster and safer for employees to store and pick goods. In our next-generation facility, Sequoia can hold more than 30 million items, making it five times bigger than our first deployment of this system in Houston, Texas, and helping us store products closer to customers for faster deliveries.

The system coordinates the efforts of thousands of mobile robots and a suite of robotic arms to bring items to employees at ergonomic workstations, where they can do all their work with more comfort and safety in their power zone, between mid-thigh and mid-chest.

I encourage you to read the press release for more details, which highlights other robots and automation technologies employed.

What are some of the benefits achieved? According to Amazon, “Within these sites, we’ve reduced fulfillment processing times by up to 25%, enhanced shipping accuracy, and increased the number of items available for Same-Day and Next-Day Delivery.” The company adds that automation systems “like Sequoia, Cardinal, and Proteus will play an important part in supporting our company-wide safety objectives. We expect these sites to meaningfully build on the over 30% improvements in safety we’ve made over the last several years by improving the ergonomics and reducing the amount of heavy lifting across these facilities.”

You can only hang on to the past for so long. The future ultimately catches up to you, and if you don’t let go and move forward, you will be left behind and never catch up.

“Stop Me If You Think You’ve Heard This One Before”

If you’re a fan of The Smiths, you’ll recognize that song, which is what I started humming when I read the following:

“We envision a future where global supply chains run as seamlessly as today’s most intuitive consumer technologies, optimizing real-time decision-making through AI and machine learning.”

Where did I read this? Name any supply chain or logistics software vendor and it would be a good guess. There’s a version of this on most of their web pages. But this version came from Auger, a new startup founded by Dave Clark, Amazon’s former CEO of Worldwide Consumer. How is Auger different? Here’s a blurb from its website:

Traditional supply chain management is fragmented, relying on incompatible systems and inefficient workarounds. Many companies are stuck with “Franken-software” — patched-together solutions that fail to communicate effectively. Auger is different. We integrate deeply with existing systems, use AI to automate routine processes, and deliver a cohesive user experience that feels intuitive and natural, letting your team focus on what matters: driving growth, innovation, and sustainability.

I haven’t been briefed by the company or seen a demo yet, but the Achilles’ heel of all these solutions (which, to be clear, I am a big advocate of) is getting a critical mass of trading partners connected to them (especially the small ones), and then getting them to share timely and accurate data so that they can synchronize their plans and respond to exceptions faster and more intelligently. Simply put, the software is the easy part; getting timely, accurate, and complete data from a large and ever-changing network of trading partners has been (and continues to be) the tougher nut to crack.

And with that, time to read some emails.

Have a meaningful weekend!

Song of the Week: “Route 66” by Depeche Mode