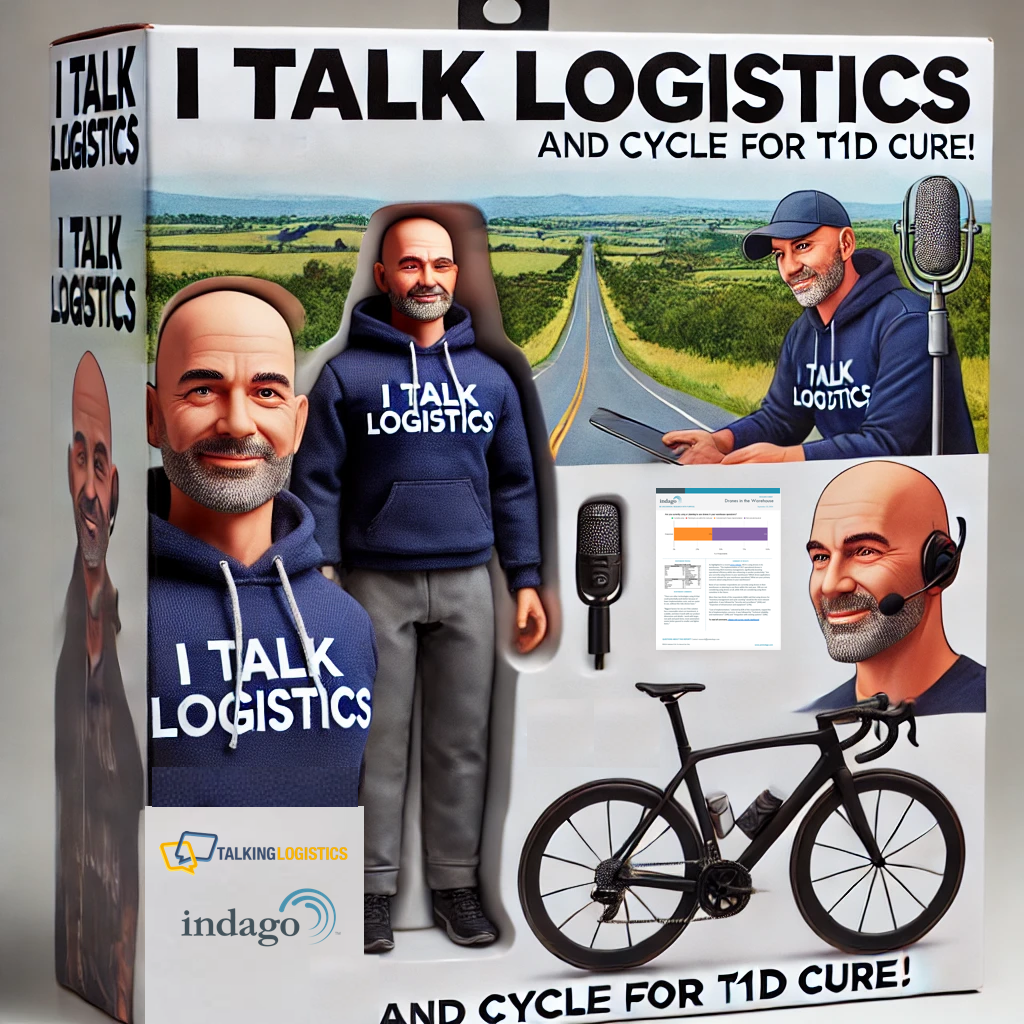

After months of working with a supplier in China, and numerous prototypes and design changes, the action figure depicting me as a logistics analyst and cyclist finally shipped! Here is the photo the supplier sent me:

Unfortunately, with the 125% tariffs being levied on imports from China, I will lose more money accepting the shipment when it arrives, so I plan to abandon the shipment at the port. For all of you who have been waiting cash in hand to spend $19.99 on “Adrian the Action Figure,” my sincere apologies. Maybe I’ll start a GoFundMe page to see if I can get it manufactured in the USA instead.

Moving on to more serious matters, here’s the supply chain and logistics news that caught my attention this week:

- Trump Pauses ‘Reciprocal’ Tariffs, but Hits China Harder (WSJ – sub. req’d)

- China strikes back with 125% tariffs on U.S. goods as trade war intensifies (CNBC)

- European Union to put countermeasures to U.S. tariffs on hold for 90 days (CNBC)

- Apple airlifts 600 tons of iPhones from India ‘to beat’ Trump tariffs, sources say (Reuters)

- Amazon considers $15 billion warehouse expansion plan (Bloomberg)

- Loftware Acquires BL.INK, Expands Product Identification Capabilities with Link Management and Connected Packaging

- Cargado raises $12M to build integrated cross-border freight marketplace

- 1Logtech Closes $1.5M Seed Round to Accelerate AI-Driven, No-Code Integration Platform for Transportation

- Optilogic Closes $40M Series B to Accelerate Development of Breakthrough Optimization and Decision-Making Platform

- N4EA Launches Diagnose + Adapt: A Game-Changing Engine for Predictive Supply Chain Risk in an Era of Global Volatility

- Gap Reports Reduced Injuries, Increased Morale with Boston Dynamics’ Mobile Warehouse Robot (Manufacturing.net)

- GNC streamlines inventory management with drones (CSA)

- Greenlane and Volvo Partner to Drive Commercial Electrification

Who Cries Uncle First on Tariffs

Just when you think this tariff business can’t get any more crazy and unpredictable, it does. You can read some of the links above for details, but I suspect you already know.

The bottom line is that after all the pomp and circumstance of last week’s so-called Liberation Day, “President Trump walked back his steep tariffs on nearly 100 nations that had taken effect just hours earlier, a shocking reversal that sent stocks soaring even as Trump announced simultaneously that he would raise levies on Chinese imports to 125% [not including the 20% fentanyl-related tariff imposed in February and March],” as reported by the Wall Street Journal.

“Trump said [on April 9] that his 10% baseline tariff on virtually all imports would stay in effect. But he implemented a 90-day pause for the higher, so-called reciprocal rates he had announced a week earlier on nations the administration views as ‘bad actors’ on trade—except for China.”

As a result, The European Union announced yesterday that it will pause its first tranche of retaliatory tariffs on U.S. goods for 90 days too. In a tit-for-tat move, China announced that it’s raising its tariffs on U.S. goods to 125% from 84%.

Talk about a yo-yo approach to global trade management and foreign relations!

It seems to me that we’re playing a game of “Who cries uncle first,” but it’s really a game with no winners. To pile on the idioms, we’re throwing out the baby with the bathwater, then setting the house on fire too.

But like the weather in Boston (where it was snowing this morning), if you don’t like what’s going on with tariffs, just wait a minute; it will change again soon enough.

Drones and Robots in the Warehouse

As I wrote last August in “Walmart And IKEA: Drone Delivery Vs. Drones In The Warehouse,” the business case for using drones in warehouses and yards is much stronger at the moment than using them for last-mile delivery — despite the recent developments with the FAA and its plans to expand use of drones for deliveries and other services.

The latest example of using drones in the warehouse is health and wellness specialty retailer GNC. As reported by Dan Berthiaume at Chain Store Age, “GNC [has] implemented the drone-based Corvus One autonomous inventory management system to more accurately and efficiently track and store inventory in its distribution centers in Indiana and Arizona.” Here’s more from the article:

The drones operate throughout the day during business hours to keep up with GNC’s high order volume. According to the retailer, the drones have improved inventory accuracy, reduced shrinkage, and minimized human errors.

By automating daily cycle counts, GNC says the drones also have freed up labor and material handling equipment, enabling faster order fulfillment and more efficient warehouse operations.

Drones just add to the other robots already roaming the aisles in warehouses. The Gap, for example, “announced the results of deploying Stretch, Boston Dynamics’ automated mobile manipulation robot, in its warehouses,” according to Nolan Beilstein at Manufacturing.net. Here’s more from the article:

[The Gap] wanted to assess the robot’s ability to move a variety of boxes that contain items like denim jeans and T-shirts. According to Gap, Stretch allows one to two inbound department employees to process 10,000 cases daily, a task that typically requires 12 to 15 workers. The company also reported reduced injuries, lowered turnover and increased employee morale.

If you haven’t been paying attention, the warehouse of the future is already here, and people are playing fewer roles (and different ones too) than they have in the past.

And with that, it’s time for me to cry uncle and get on with the weekend. Have a meaningful weekend!

Song of the Week: “Space Song” by Beach House